Production Orders & Shift Tracking

Track your shifts and production orders

With TrendOEE, you can track production efficiency based on both shift changes and production orders. Get a clear overview of performance per shift and gain insights into how planned orders actually unfold in practice.

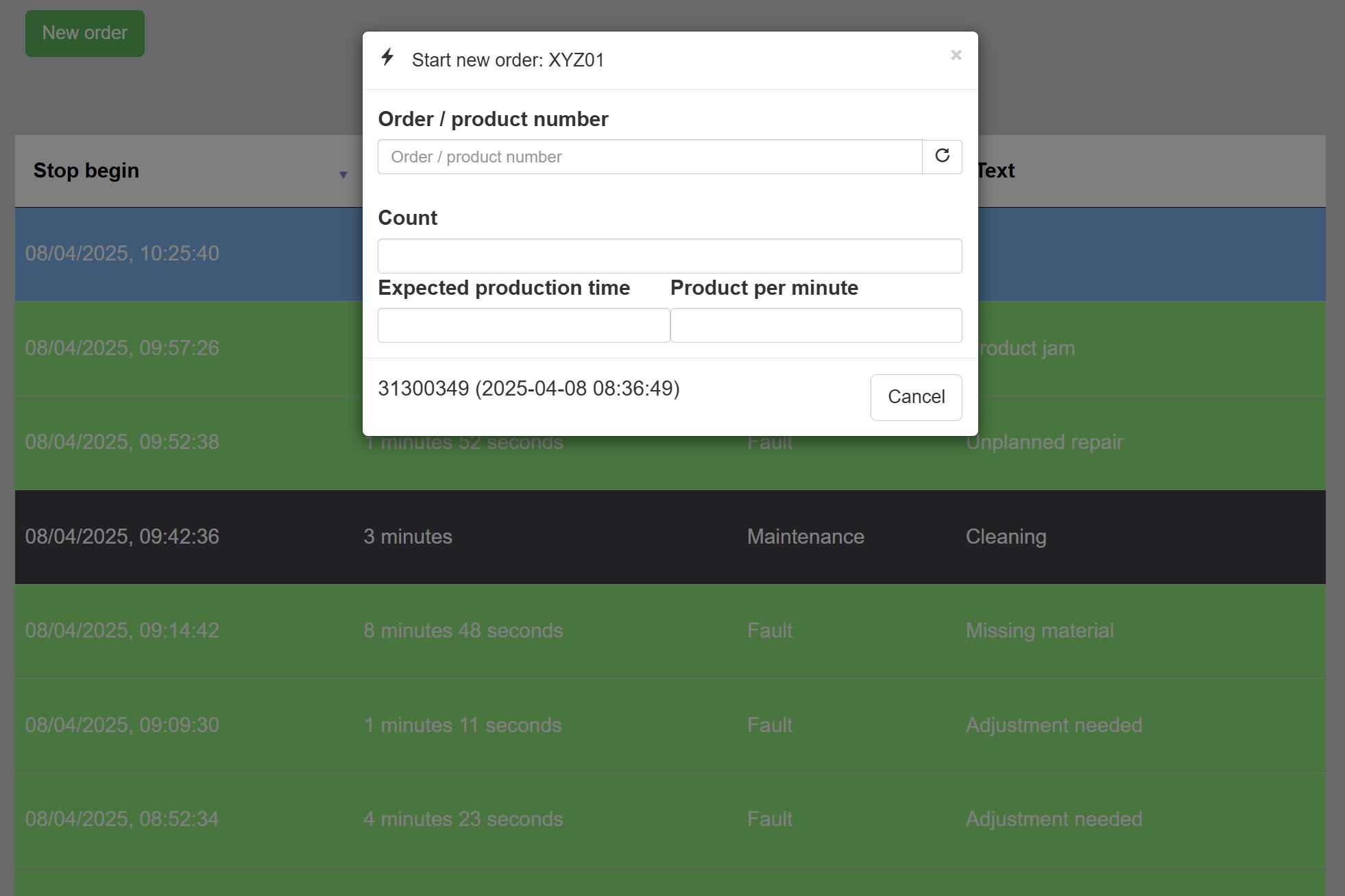

Order planning integration

Order tracking

Integrate your production orders via tablet, barcodes, API calls from your ERP system, or manual inputs – and monitor output, stops, waste, and efficiency for each order. This creates alignment between planning and reality – and documents performance.

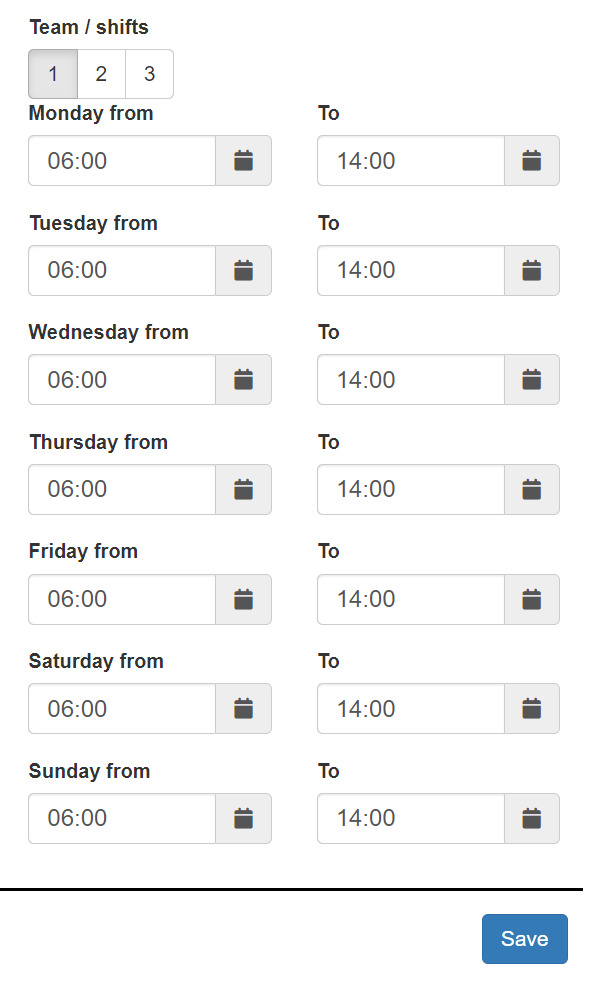

Shift changes and benchmarking

Compare shift performance

TrendOEE allows you to define shifts and track performance per team. See how different teams perform – and enable smoother handovers between shifts with notes on orders, faults, or machine issues.

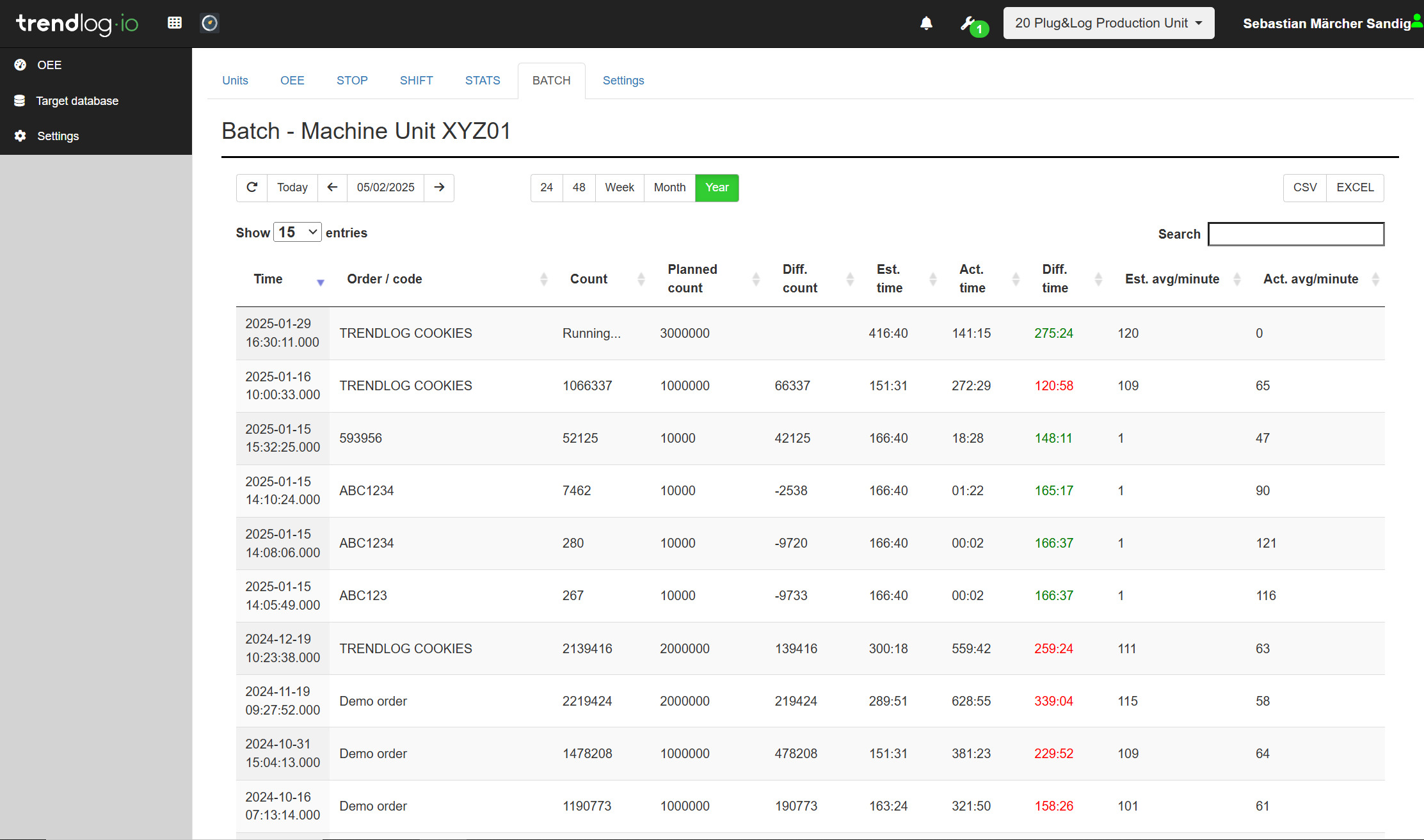

Reporting and analysis

Track actual order performance

Automatically generate reports for each completed order: How long did it take? What stops occurred? How much was scrapped? TrendOEE gives you clear, data-based answers – so you can learn from each process and optimize future ones.

All-in-One Solution

A part of TrendOEE

This feature is fully integrated into TrendOEE and the broader Trendlog.io platform. That means your data is automatically connected with stop causes, maintenance, energy consumption, and quality control – giving you one complete overview.

Ready to take control?

Book a free demo and get a walkthrough of how you can track performance per shift and order – and use data to optimize your operations, flow, and planning.