Maintenance Management

Maintenance Planner

Gain full control over all maintenance and service tasks – digitally and proactively. Maintenance Planner helps you prevent breakdowns and keep your production running smoothly.

Avoid downtime and get control over your maintenance

Maintenance Planner makes it easy to schedule and document all service and maintenance – across machines, locations, and teams. Watch the video and see how you can shift from reactive to proactive maintenance.

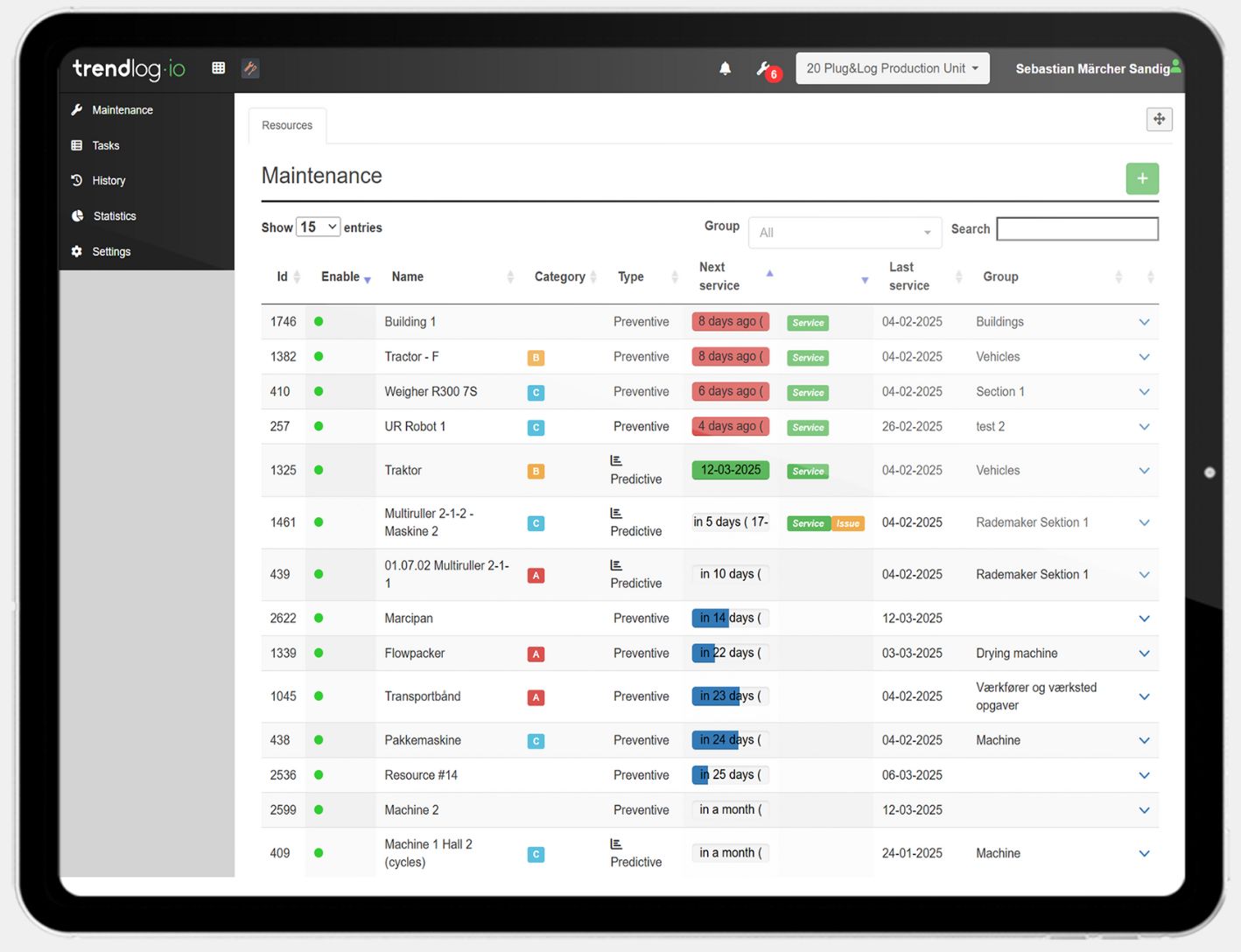

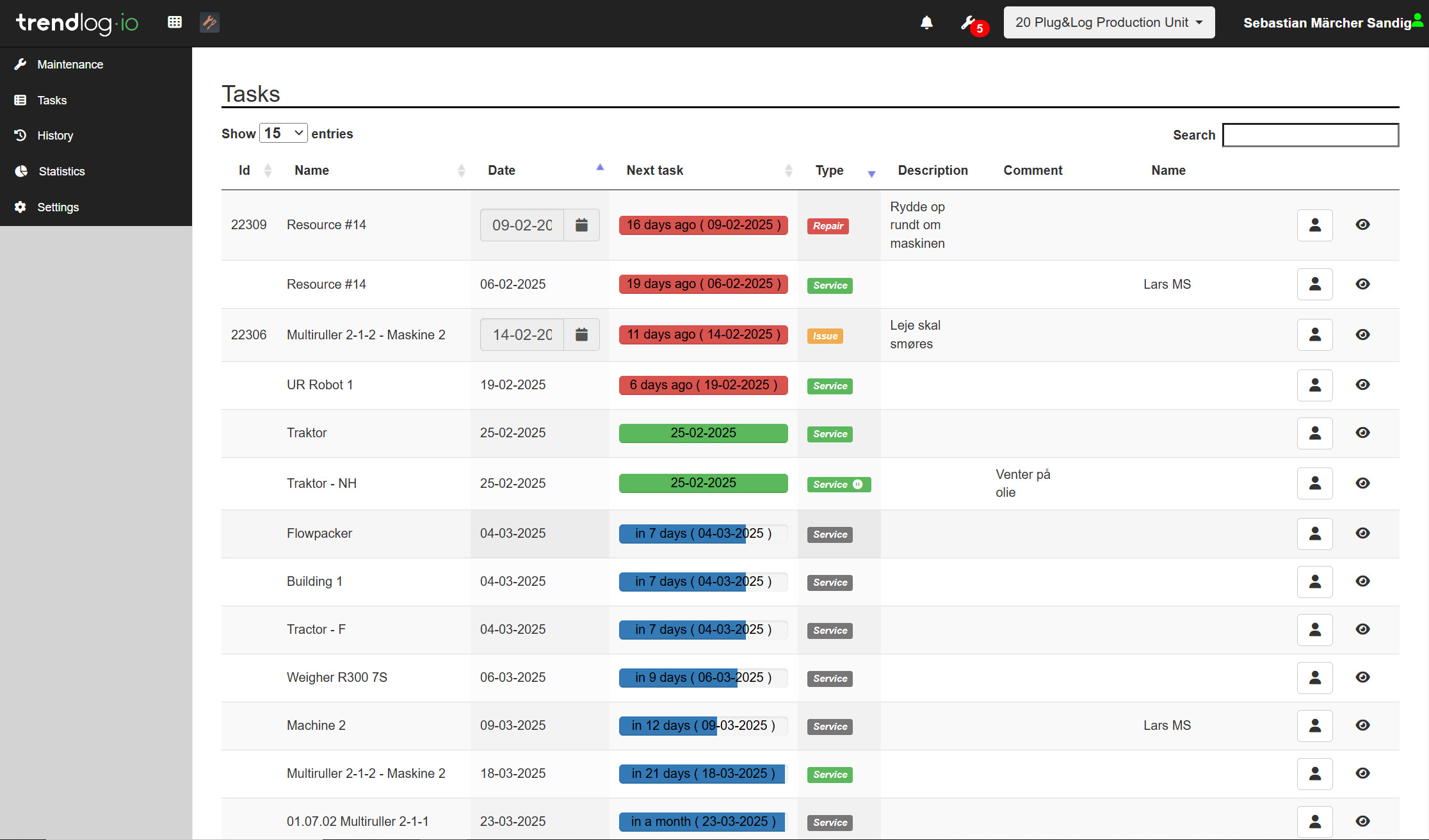

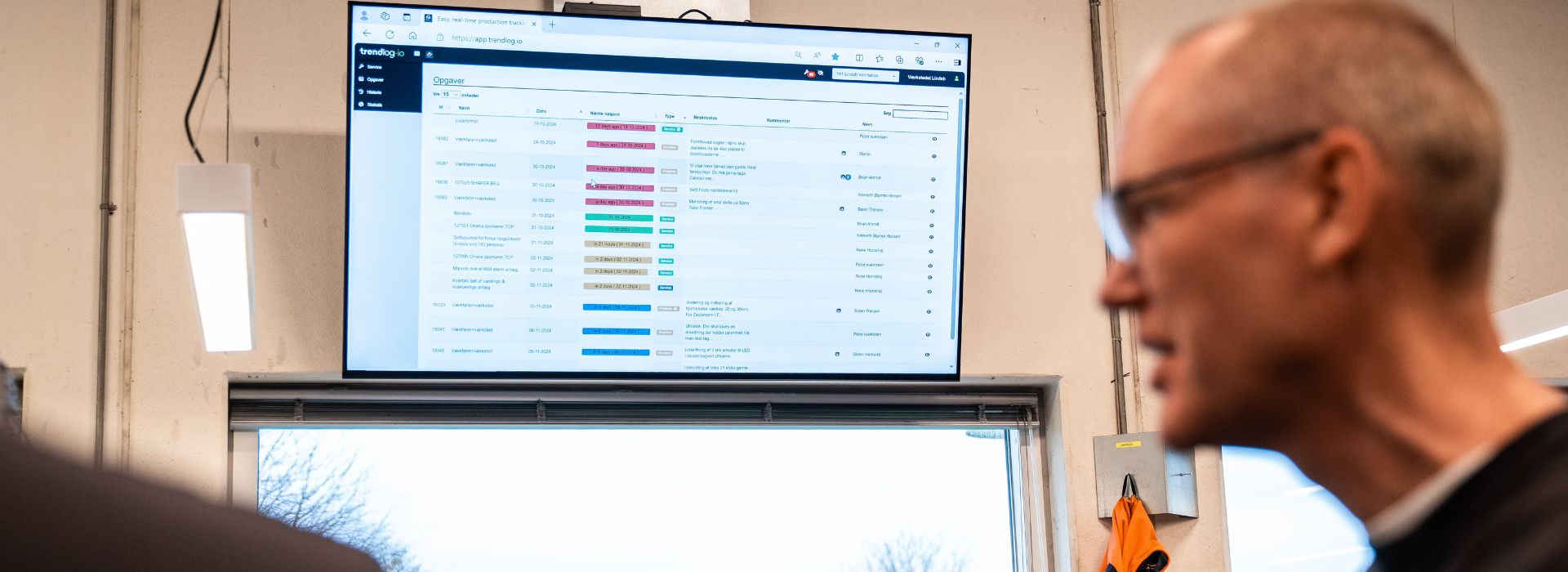

CMMS

Efficient maintenance management

Get a complete overview of all maintenance tasks – planned or urgent. Assign tasks, set deadlines, and follow up with just a few clicks. One platform for the entire team.

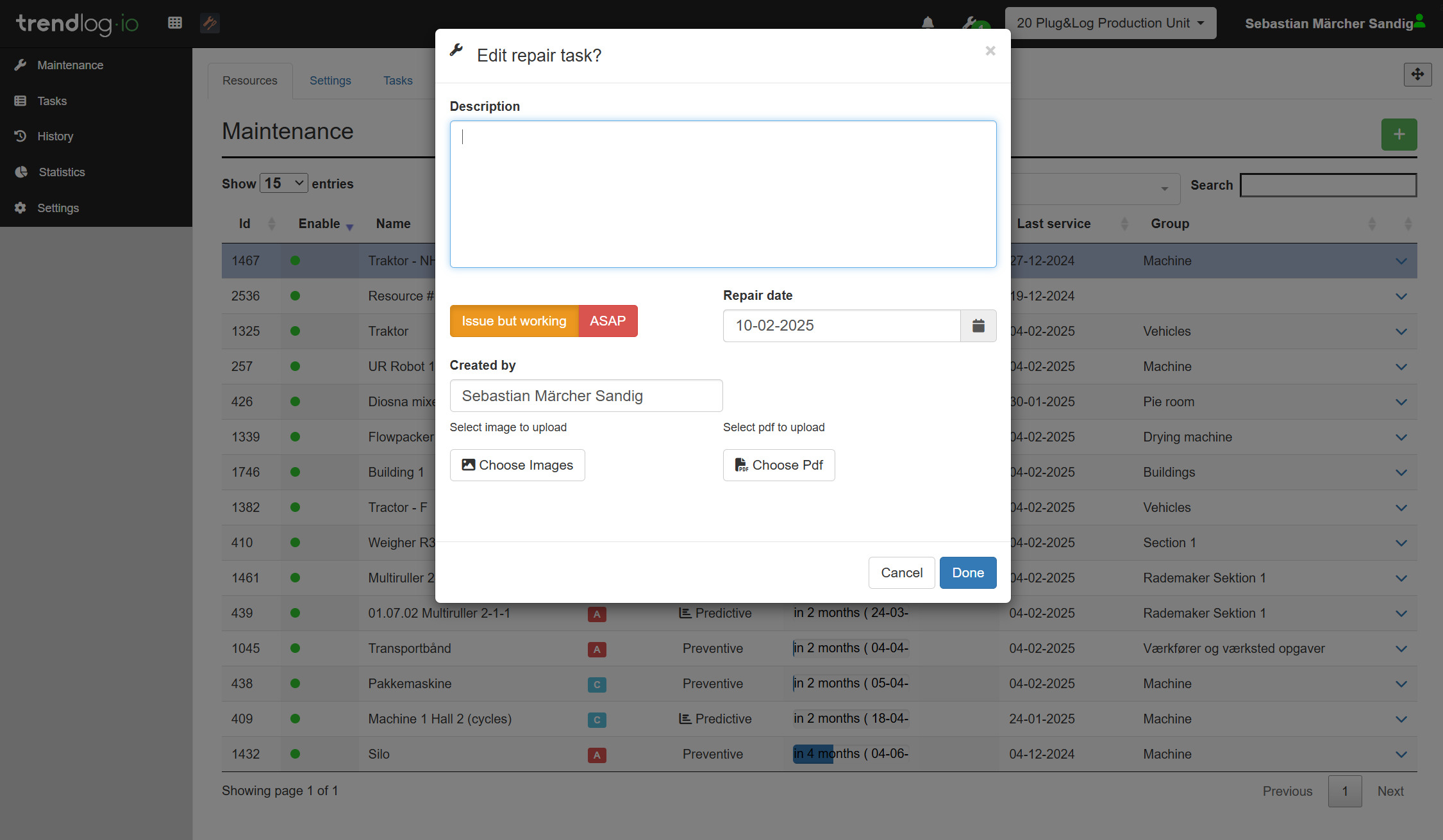

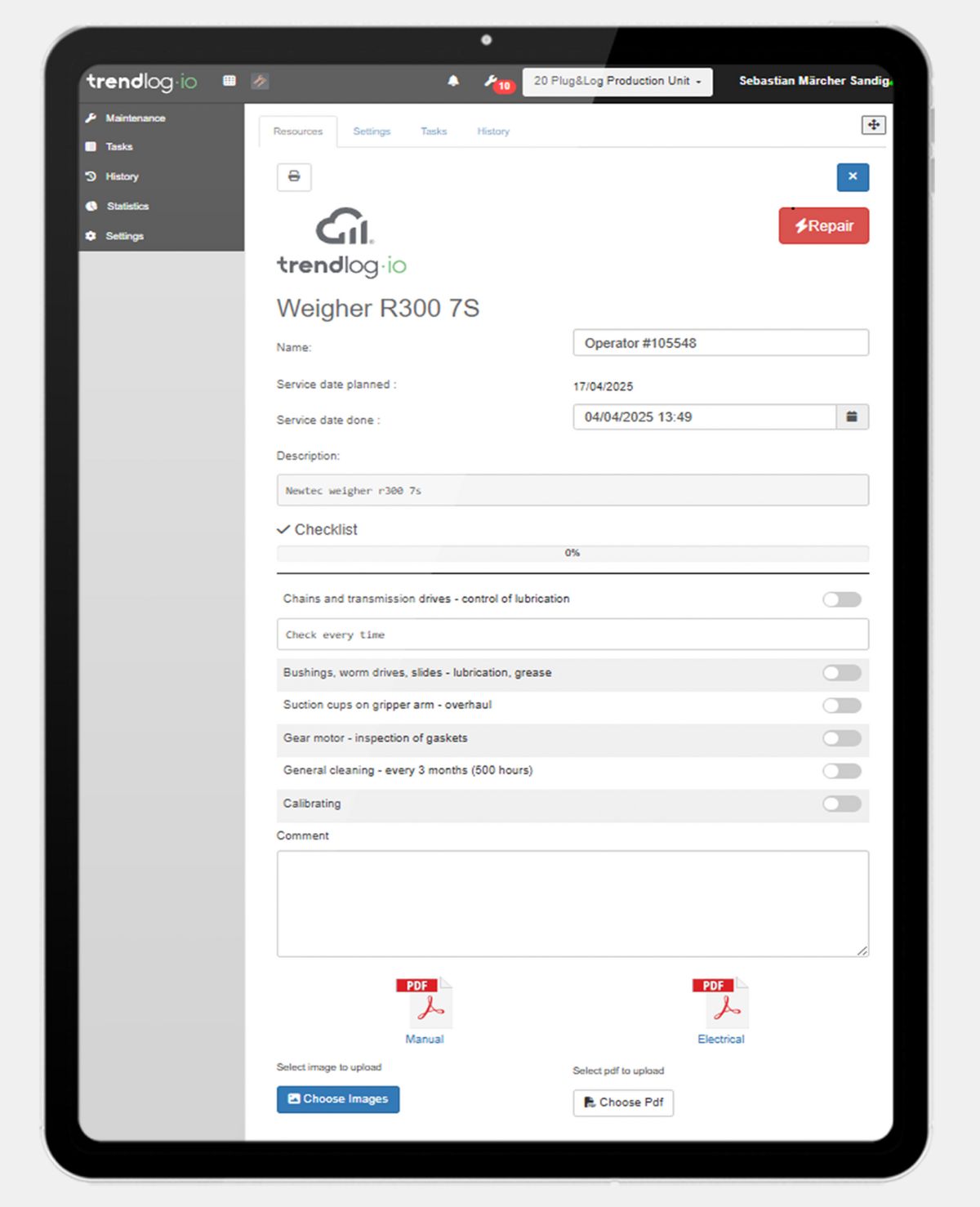

Digital documentation

All documentation in one place

All maintenance, repairs, and service activities are logged digitally. Track machine history and keep documentation updated and easily accessible – at all times.

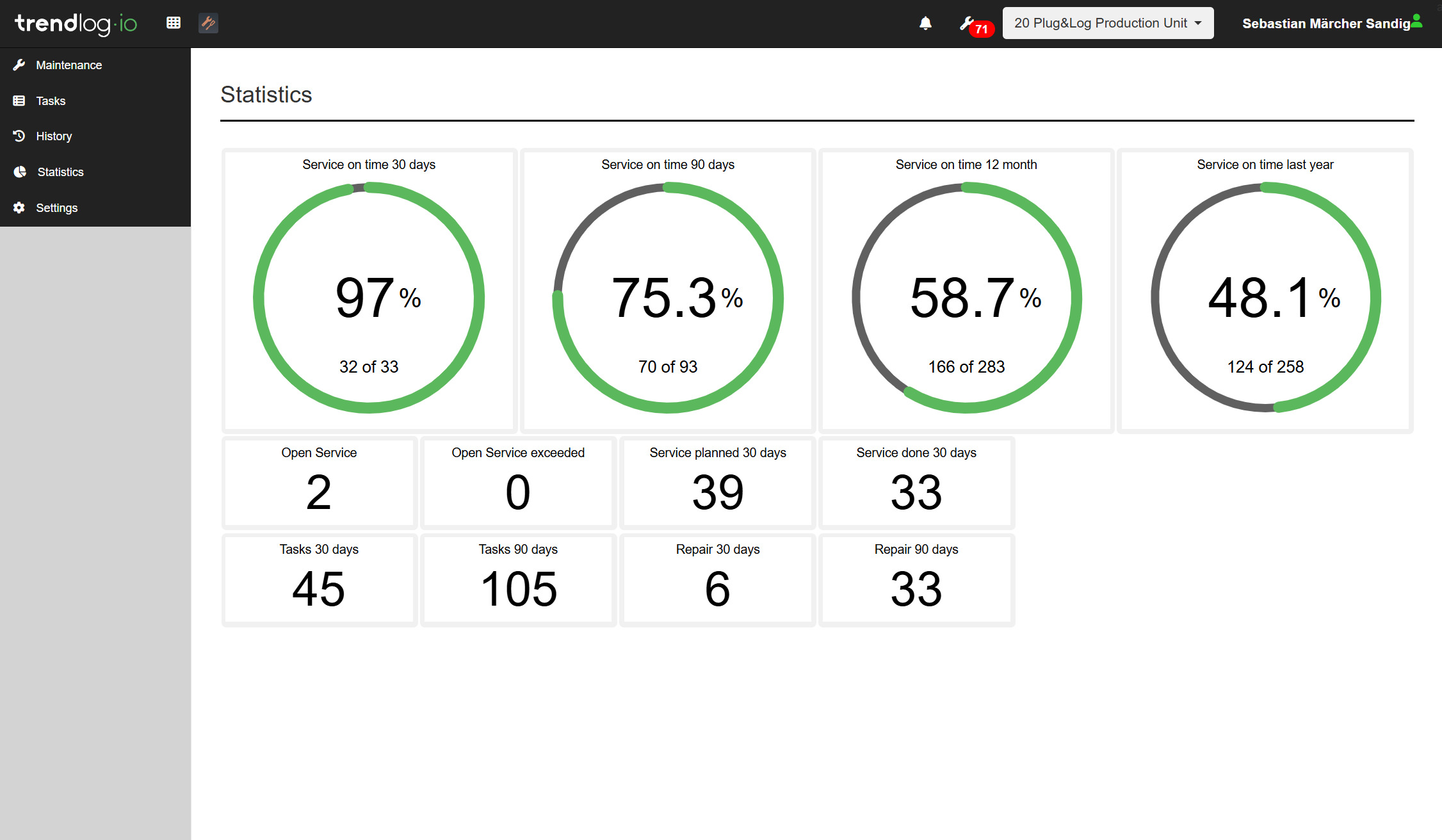

Downtime insights

Prevent costly breakdowns

Schedule tasks based on actual runtime or fixed intervals. Maintenance Planner helps you detect patterns and address issues before they become critical.

Multi-site CMMS

Manage across factories

Oversee maintenance across multiple factories or departments. View status and plan tasks collectively – without losing the overview.

Document management

One place for all machine documentation

Store manuals, service contracts, spare parts lists, and documentation in one place. Give technicians quick access directly from their mobile – no clutter, no binders.

Fast setup, huge impact.

We’ll get you started quickly with setup and import of your machines and maintenance tasks. You’ll be up and running in just a few hours – with full support from our team along the way.

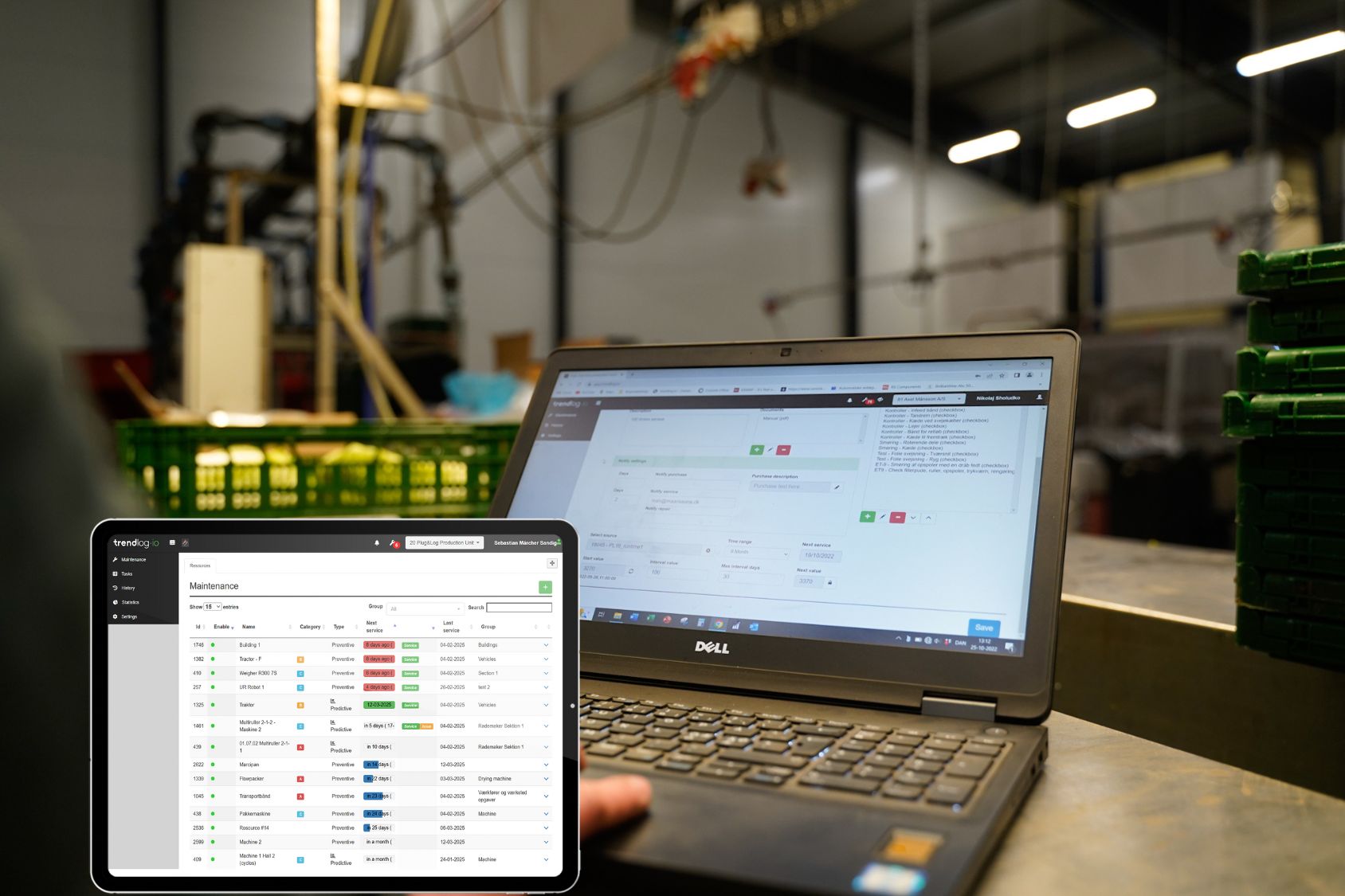

CASE: Maintenance

How Axel Månsson reduced their maintenance costs

The story of how one of the biggest vegetable producers in Northern Europe manages to maintain over 200 machines all year long to avoid expensive breakdowns and repairs.

What does Maintenance Planner cost?

Maintenance Planner makes it easy to plan, document, and follow up on all maintenance activities – whether you have 10 or 300 service tasks. Contact us for a quote tailored to your needs.

PRICE / MONTH, STARTING FROM

€100-200

FOR 50-300 SERVICE PLANS

Included in the subscription:

- Planning and assignment of service tasks

- Automatic documentation and service history

- Unlimited users and technician access

- Document management (manuals, images, etc.)

- Mobile- and tablet-friendly interface

- Onboarding support and training

Frequently Asked Questions

How does Maintenance Planner help us stay on top of maintenance?

It gives you full control of all scheduled and unplanned tasks across teams, sites, and machines – with planning, documentation, and execution all in one place.

Can we schedule maintenance based on runtime or time intervals?

Yes – you can plan tasks based on operating hours, calendar intervals, or ad-hoc needs. This allows for predictive and preventive maintenance workflows.

How do technicians access their tasks?

Technicians can access their assigned tasks from a tablet or mobile device – complete with machine info, documents, checklists, and the ability to complete and comment on tasks digitally.

Can we manage documentation and service history?

Yes – you can store manuals, service contracts, checklists, and photos in one place. The system keeps your service history updated and easily accessible.

Can we manage maintenance across multiple sites?

Yes – the platform supports multi-site setups, so you can manage machines and teams across different locations with full visibility and control.

Ready to take control of your maintenance?

Get 30 days of free access to Maintenance Planner and experience just how easy it is to plan and document your maintenance – with no commitment.