Take control of production, maintenance, and energy consumption – with one system.

Trendlog.io provides real-time data from your production, enabling you to act proactively, reduce waste, and maximize uptime – all from one unified platform.

All-in-one solution for smart manufacturing.

Gain insights, reduce waste, and optimize maintenance and energy usage – all within one intuitive SaaS solution. Trendlog.io consolidates your data in one place, helping you make better decisions, improve operations, and run a more efficient and sustainable production.

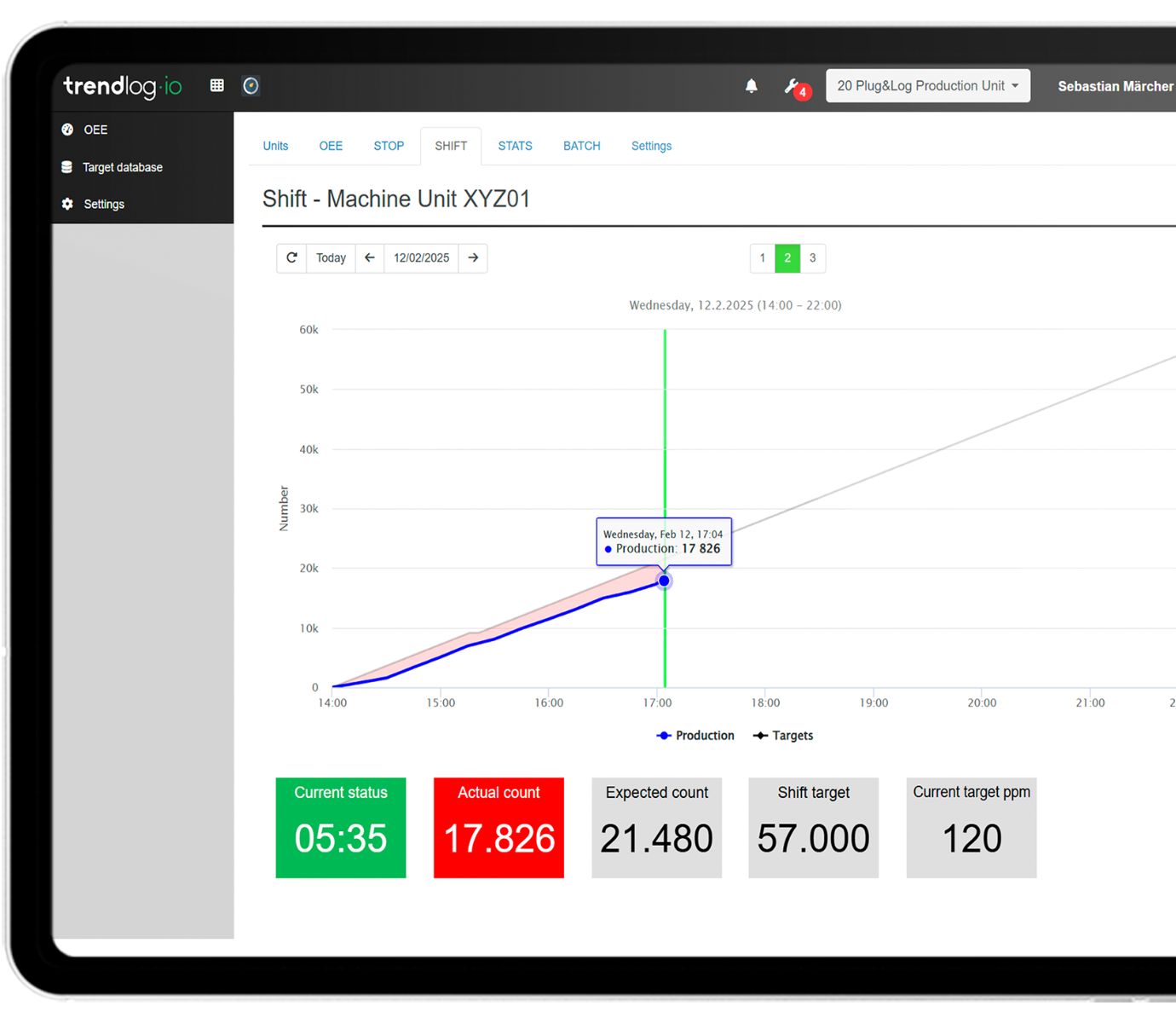

TrendOEE

- LIVE OEE from your machines

- Real-time insights into stop causes

- Up to 25% increased efficiency

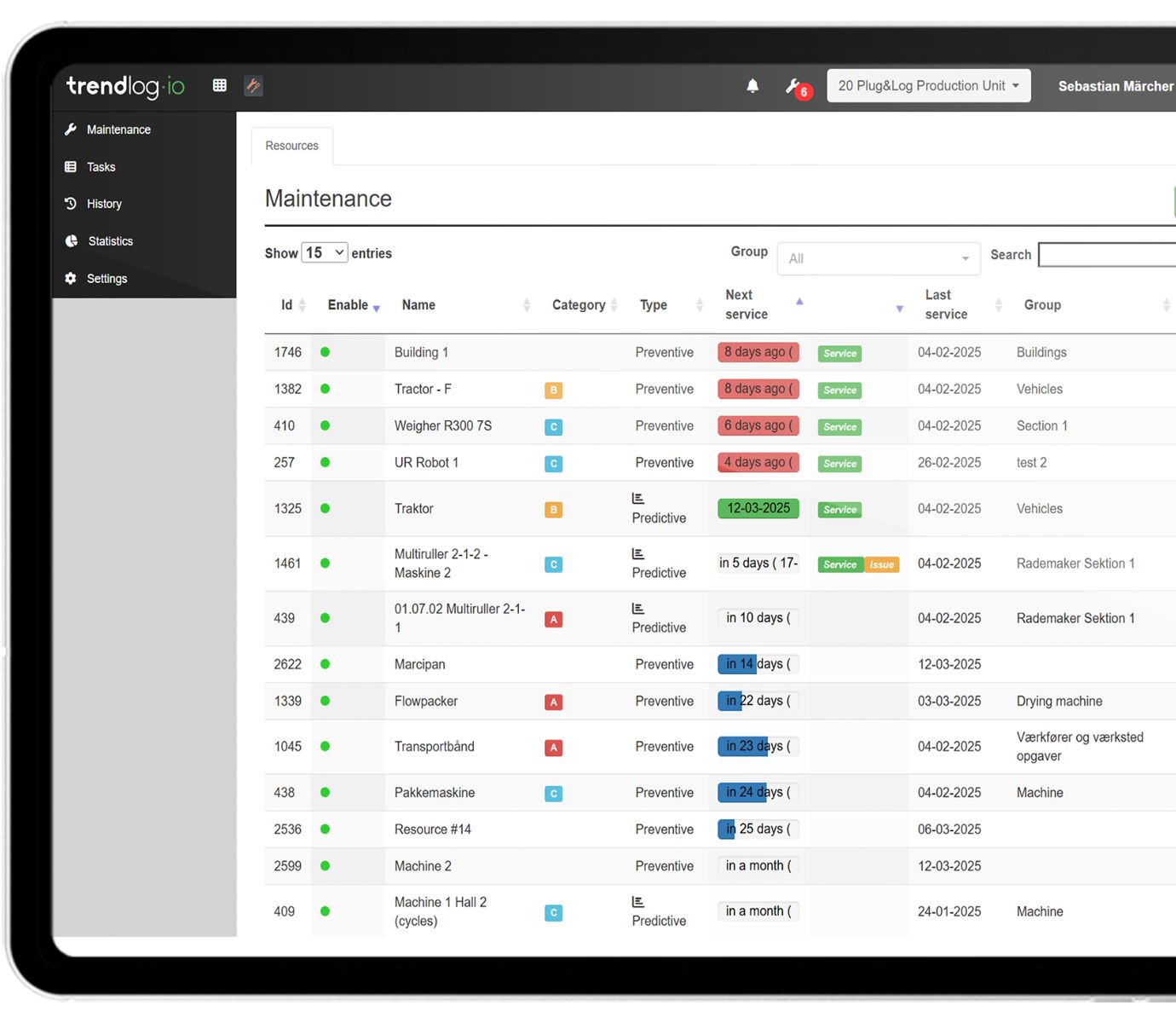

Maintenance PLANNER

- Simple maintenance management

- A great alternative to CMMS and Excel

- Prevent costly breakdowns

- Extend machine lifetime

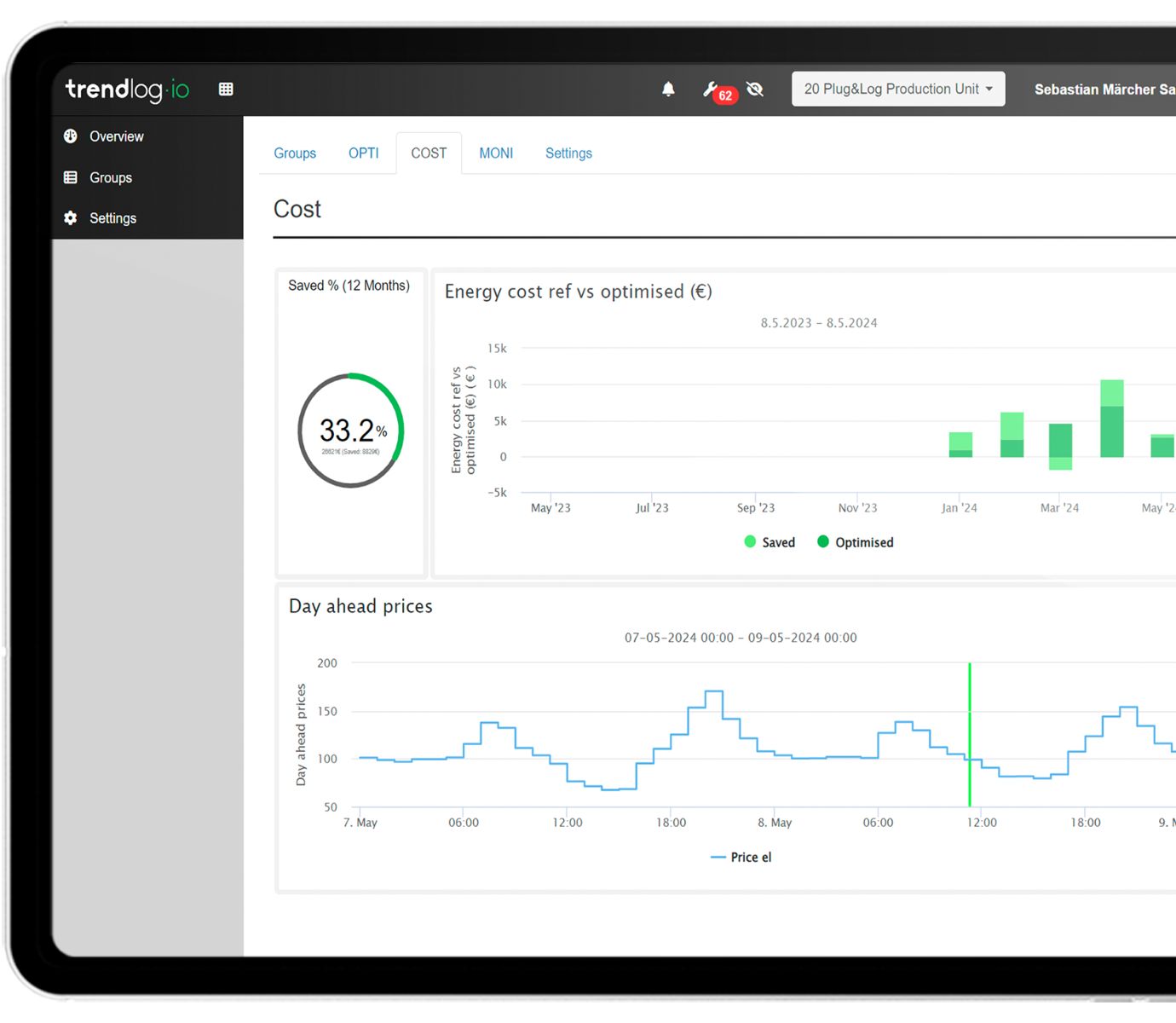

TrendENERGY

- Full overview of factory consumption

- Supports EPD and ESG reporting

- Enable energy optimization

Why Trendlog.io?

Without Trendlog.io

- Manual data handling

- Machine breakdowns

- Energy waste

- Inefficient production

- Too many systems

- No continuous improvement

With Trendlog.io

- Real-time insights

- Key KPIs in one place

- Faster decision-making

- Smart maintenance

- Paperless production

- No expensive IT projects

- Historical data in one place

- Energy optimization

- Seamless data integration between systems

CASE: OEE & Maintenance

How LINDAB optimizes their production & maintenance

The story of how a multinational company manages their maintenance across several sites, reducing their cost of operations and increasing their efficiency

Frequently Asked Questions

How can Trendlog.io help optimize our production?

Trendlog.io collects real-time data from your machines, meters, and processes and visualizes it in one intuitive platform. This gives you a complete overview and helps you reduce downtime, waste, and inefficiencies – all without manual work or spreadsheets.

What kind of data can we collect with Trendlog.io?

You can collect data from machines (runtime, output, stoppages), utility meters (electricity, water, gas), quality checks, and maintenance tasks. Both digital and analog signals are supported using our IIoT hardware and open API integrations.

Do we need to invest in IT development to get started?

No – Trendlog.io is designed to be easy to implement. Our hardware is plug & play, and the cloud platform works straight out of the box. You don’t need custom development or long IT projects.

Can both operators and managers use the platform?

Yes – operators can use tablet-friendly tools like TrendSTOP and TrendFORMS, while managers can access dashboards, reports, and real-time KPIs. The platform is built for everyone – from shop floor to management.

What systems can Trendlog integrate with?

We support API integration with ERP, BI, and planning systems like SAP, Microsoft Dynamics, Monitor ERP, and Power BI – enabling two-way data exchange and seamless workflows.