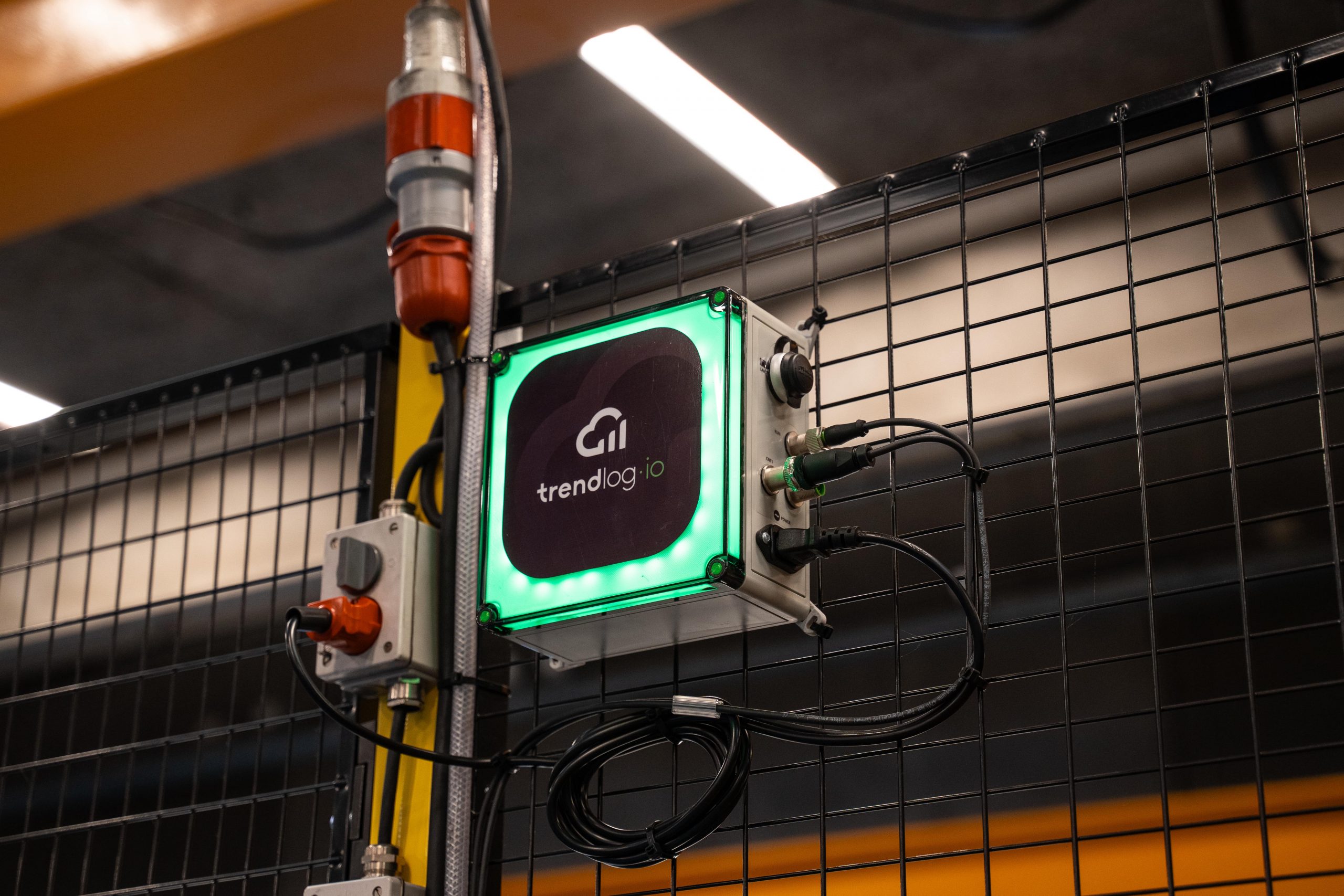

IIoT Edge Device

Trendlog COLLECT

Simple data collection from machines and meters – directly from the production floor. Trendlog COLLECT is your IIoT gateway and the foundation for real-time digital insight and optimization.

Simple, fast, and flexible data collection

Trendlog COLLECT is a compact, preconfigured IIoT device that makes it easy to retrofit data integration to both new and legacy machines. It connects your production lines, meters, and PLCs directly to Trendlog CLOUD – without complex configurations.

Intelligent data collection

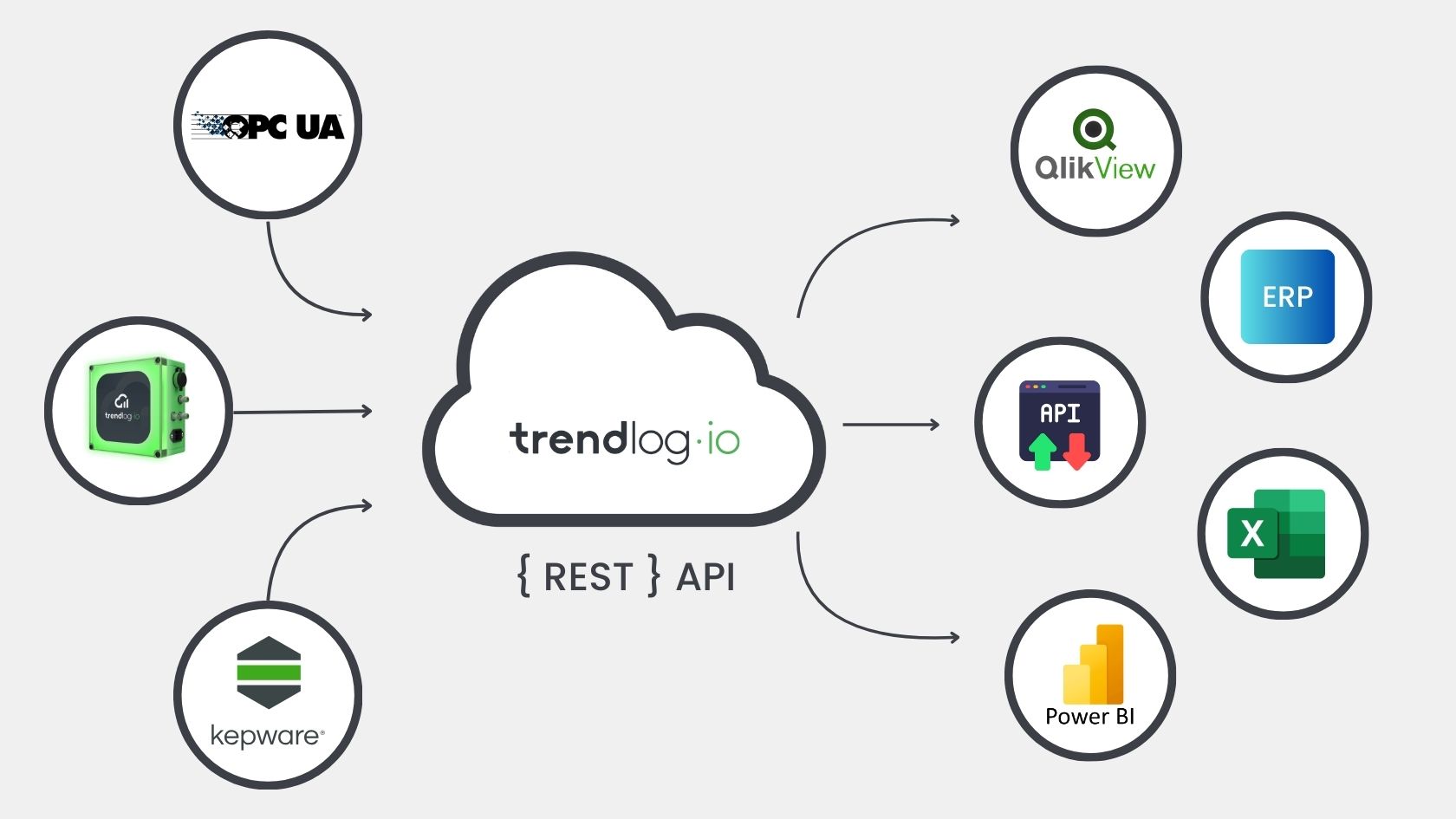

Collecting your data

Collect data from all types of machines and systems – both digital and analog. With our COLLECT boxes and open API, you can integrate ERP, BI, and planning tools to create one unified data foundation.

Quick installation

Easy setup – ready to use

Trendlog COLLECT comes preconfigured and ready to use upon delivery. It requires minimal wiring, takes up very little space, and can be installed by your local electrician or one of our experienced integrators. No IT complexity – just plug & play.

Integrations

One device – many connections

A single COLLECT box can connect directly to one machine with operational and counter signals, or to up to 8 machines and several meters on the same production line. It serves as a local gateway and supports communication with PLCs, energy meters, and Extender modules – with no need for special hardware.

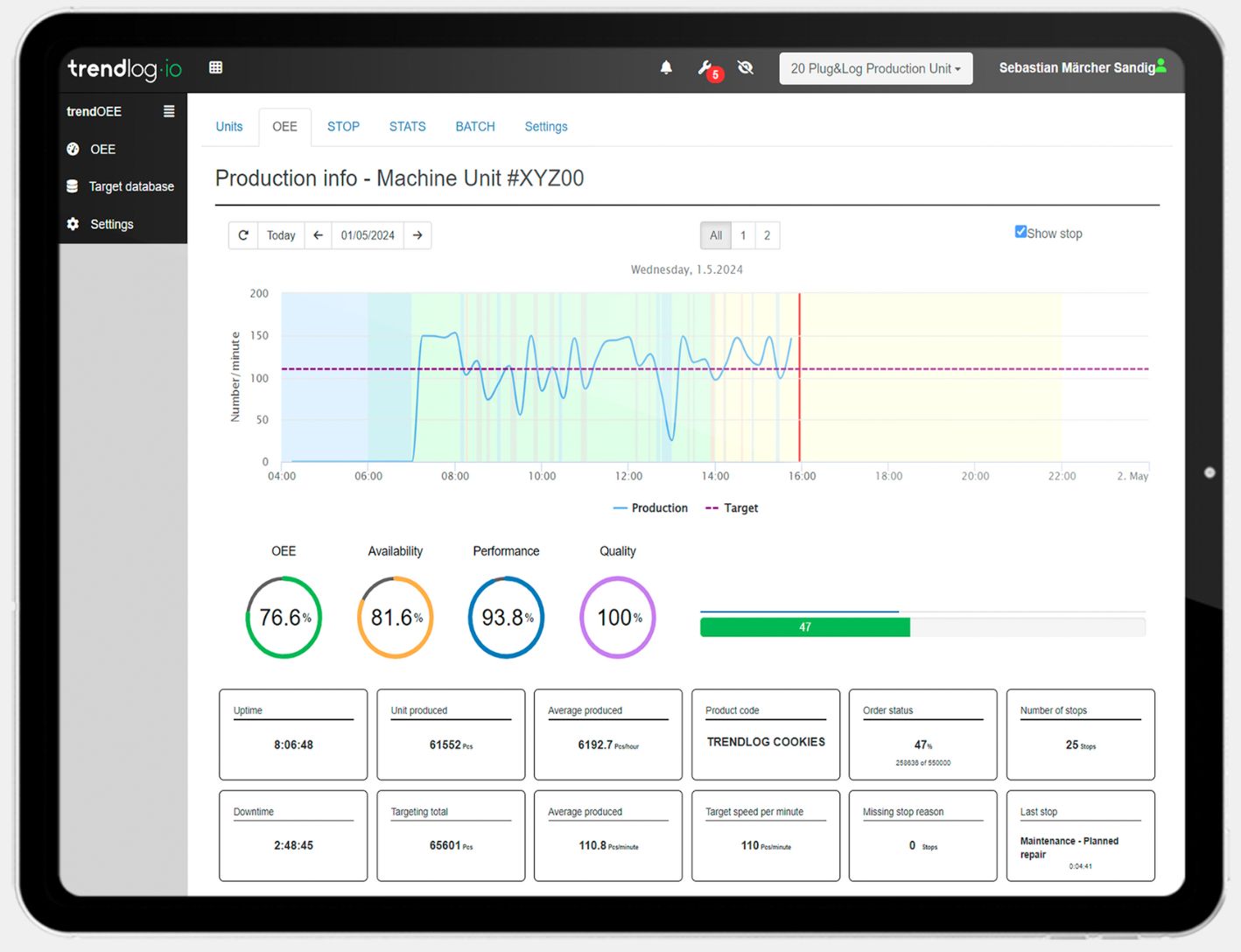

Turn data into value

The key to the Trendlog platform

Trendlog COLLECT is designed to act as the link between your physical equipment and the Trendlog CLOUD platform. It enables LIVE data collection for TrendOEE, MaintenancePlanner, TrendENERGY, and TrendFORMS – unlocking automated insight and action across your production.

What does Trendlog COLLECT cost?

Trendlog COLLECT is our custom-developed IIoT device that makes it easy to collect data from both new and legacy machines. It acts as a gateway between your physical equipment and the Trendlog platform – with a simple one-time purchase. Contact us for a price adapted to your production setup.

PRICES FROM

€800

PER DEVICE

Included:

- Compact, preconfigured IIoT device

- Scalable and flexible

- Supports data collection from up to 8 machines and multiple meters

- Connects to Trendlog CLOUD via Ethernet, WiFi, or 4G

- Integrates with energy meters, PLCs, and Extender modules

- Easy installation by your local electrician or Trendlog partner

- Technical support and setup documentation

Frequently Asked Questions

What is Trendlog COLLECT used for?

Trendlog COLLECT is a compact IIoT device that collects machine and meter data and sends it securely to the cloud. It acts as a local gateway for real-time monitoring, analysis, and reporting.

How many machines or sensors can one COLLECT unit connect to?

One COLLECT device is typically used per machine but can connect to up to 8 machines or sensors on a production line, plus multiple meters such as electricity, water, or temperature meters.

Is Trendlog COLLECT compatible with older machines?

Yes – COLLECT supports both digital and analog signals, making it ideal for retrofitting legacy equipment without major reconfiguration.

How is the COLLECT device installed?

The device is preconfigured and plug & play. It requires minimal cabling and can be installed by your local electrician or one of our certified integrators.

What types of network connections are supported?

Trendlog COLLECT supports Ethernet, WiFi, and optional 4G modem – offering flexible installation regardless of your factory’s infrastructure.

Ready to connect your production?

Want to see how COLLECT can be connected to your machines and meters? Book a demo or get a no-obligation quote on a setup tailored to your production.