How Lindab Optimizes Their Production with Trendlog

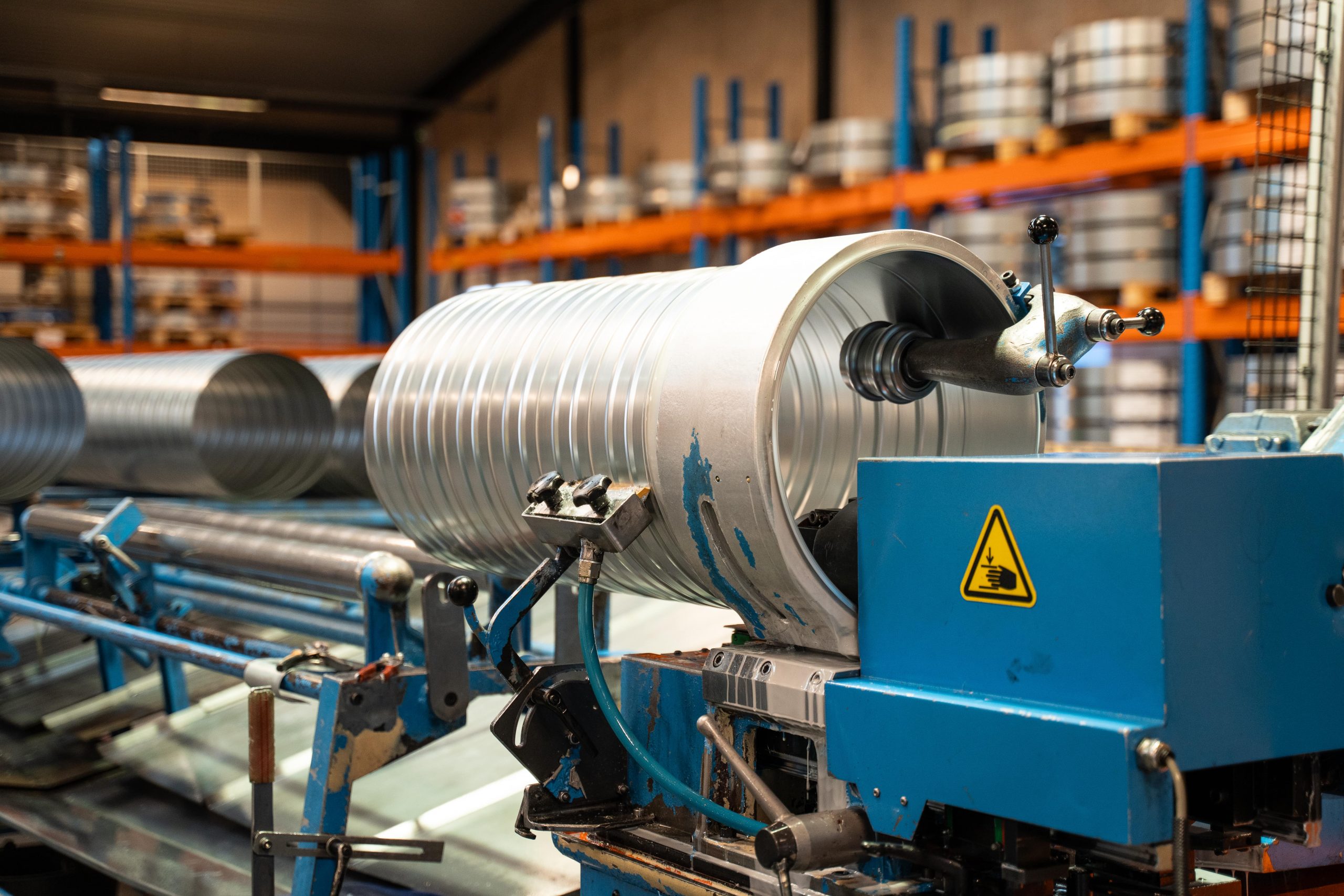

Lindab, an international company specializing in ventilation and indoor climate systems, has implemented Trendlog’s solutions at their Danish factories to optimize both maintenance and production efficiency. With locations in Haderslev, Hvidovre, Aalborg, and Viby, Lindab has embraced data-driven decision-making, leading to significant cost savings and improved oversight.

As one of Denmark’s leading manufacturers of ventilation components, Lindab needed to ensure optimal operation and maintenance of their extensive machinery, which includes over 500 machines. Previously, maintenance was often time-based, resulting in unnecessary service costs and unforeseen breakdowns.

René Hornshøj, Maintenance Manager at Lindab, explains:

“We used to over-service many machines because we lacked insight into their actual condition. This meant higher costs and wasted time.”

At the R-22 trade fair in Odense, Lindab found the perfect solution in Trendlog.io. By combining Maintenance Planner and TrendOEE, Lindab now has an integrated platform to monitor machine health and production efficiency in real time.

René elaborates:

“Trendlog’s Maintenance Planner gives us an excellent overview. We’ve transitioned from time-based maintenance to consumption-based service, which has extended the intervals between services and significantly reduced our costs. At the same time, it provides our technicians with an easy and flexible solution they can bring to the field on their iPads.”

Simultaneously, Lindab is rolling out TrendOEE, helping them analyze downtime, stoppage reasons, and efficiency on their production lines.

Niels Kammer, Production Engineer, adds:

“With TrendOEE, we can collect data from our machines and see exactly how they are performing. This allows us to identify opportunities for improvement and further optimize our processes.”

Since implementing Trendlog’s solutions, Lindab has achieved:

- Significant cost savings through more needs-based maintenance.

- Reduced downtime and fewer unexpected breakdowns.

- Clear insights into the most efficient times of day for production.

- Better planning of technician tasks and spare parts procurement.

René summarizes:

“We do far less firefighting because we’re ahead of the curve with service and maintenance. We’ve found a solution that not only works – it makes us better.”

The Future with Trendlog

Lindab plans to expand their use of TrendOEE to analyze stoppage reasons and further maximize efficiency. With Trendlog.io, Lindab has not only strengthened their production but also laid the foundation for a smarter and more sustainable future.

Trendlog’s solutions have enabled Lindab to take control of their machinery and production data. Want to optimize your production too? Contact us for a no-obligation chat or a free demo of our solutions.