Efficiency: The Path to Success for the Danish Manufacturing Industry in 2023

Digitalization and automation

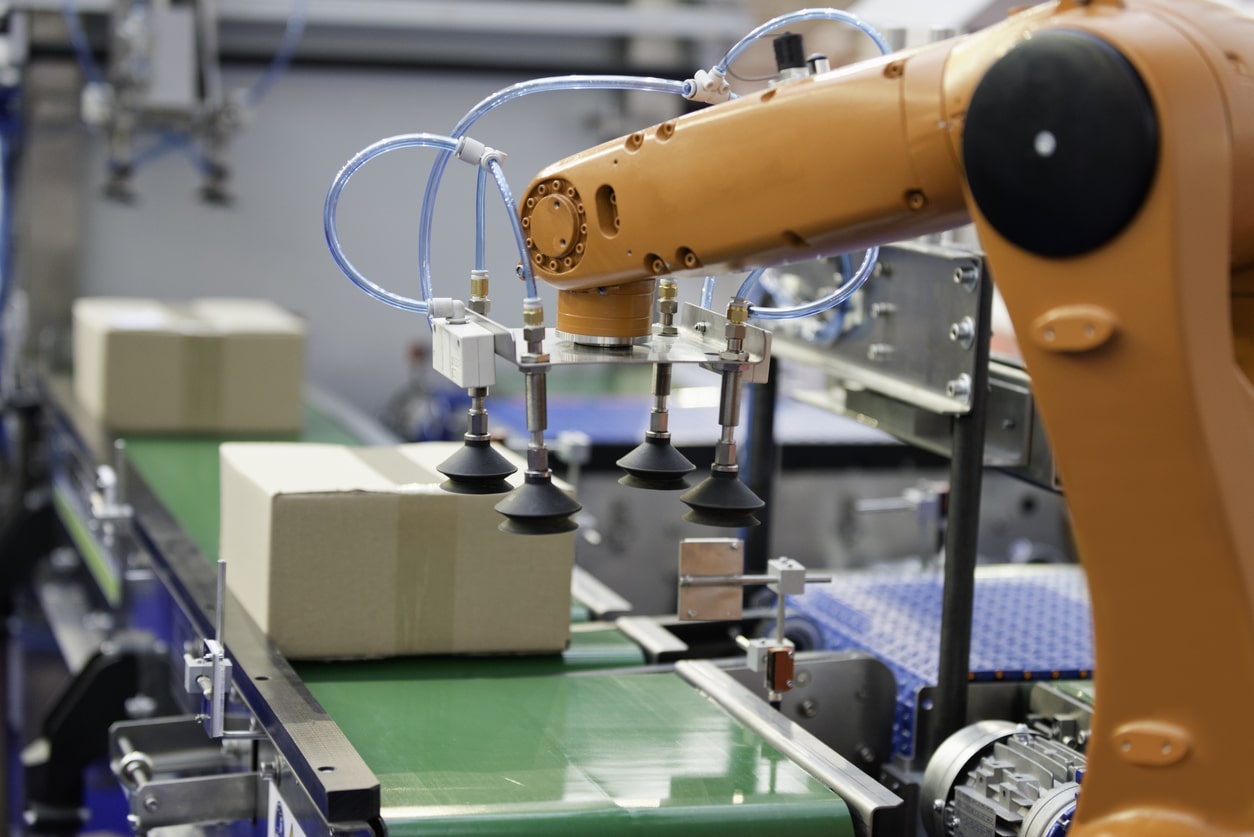

Nevertheless, it is precisely now that the Danish manufacturing industry should look towards cost efficiency, resource consumption, and overall production as an opportunity to navigate through the crisis while building healthy consumption habits that reduce waste and overconsumption. Digitalization and automation are key elements in this process of efficiency, and it applies not only to large corporations but also to small and medium-sized enterprises (SMEs). Although SMEs may be reluctant to make investments, they should take a closer look at the many benefits that come with digitalization and automation.

A crucial factor is the use of data. By collecting and analyzing real-time data from production, companies can identify bottlenecks and inefficient processes, enabling them to make informed decisions about optimizing their manufacturing processes.

Data is an invaluable resource that can lead to increased productivity, reduced downtime, improved preventive maintenance, and minimized repair needs. By harnessing data to its full potential, companies can achieve a more efficient and reliable production that contributes to enhanced competitiveness.

However, data can also play a crucial role in green transformation. By analyzing and utilizing data from production, companies can identify and reduce waste, optimize resource consumption, and minimize energy usage. This not only results in environmental benefits but also brings economic gains in the form of less waste and lower electricity bills.

Unique opportunity

The Danish manufacturing industry has a unique opportunity to embrace efficiency and green transformation. Despite the numerous challenges, we must look ahead and focus on the opportunities that lie before us.

It takes courage to invest in efficiency, but it is a relatively low-risk step towards the future. By collecting and analyzing data, as well as implementing digitalization and automation, the Danish manufacturing industry can transform challenges into opportunities.

Let us use the remainder of 2023 to build a more efficient, sustainable, and competitive manufacturing industry. Let us create a future where efficiency is the path to success, and where the Danish industry stands strong.

We have the crisis ahead of us, but we also have the tools to overcome it and create a better future. The time is now, let us come together and realize the potential in the Danish manufacturing industry! Contact us at Trendlog.io if you want to talk about your own path to efficiency and success.

Ready to take the first step?

For Danish companies there are programs like SMV:Digital and SMV:Grøn designed to help SMEs finance investments in digital and green transformation, opening the door to a more efficient and sustainable production. These programs are usually facilitated by your local “Erhvervshus”. Reach out to them and let them tell you about the opportunities for your company.

Others also read

Vi deltager i INNOVATIONSKRAFT

Vores deltagelse i projektet “Automatisering af AI drevet Energioptimering” under ordningen INNOVATIONSKRAFT sigter mod at revolutionere energiforvaltningen i fødevareindustrien. Med støtte fra EU, udvikler vi AI-løsninger for at skære energiomkostninger og CO2-udslip, fremme bæredygtighed og økonomisk effektivitet.

Great success on Automatica

Last week, a large part of the Trendlog team was in Munich at the Automatica 2022 trade fair, where we were part of Odense Robotics’ Danish pavilion. And what a week it was!

Trendlog.io presents new CEO

Per 1st of October, Trendlog.io restructured internally, and has assigned Sebastian Märcher Sandig as new CEO.