Plastics Manufacturing

In the plastics manufacturing industry, efficiency is paramount. Enhance your output, track operations in real-time, and minimize energy consumption. Trendlog’s solutions enable you to boost productivity, cut costs, and enhance sustainability in plastic production.

Unlock the full potential

Plastics manufacturers often need to balance profitability, high output and operational excellence in a competitive industry. Some of the most important KPIs are:

- Output

- Cycle time

- Quality

- Overall efficiency

The right data from your machines and production processes will enable you to make informed decisions that can make a big difference on your overall efficiency. We have that solution for you.

The applications Trendlog offer

Realtime Production

Realtime Production offers a full real-time production overview, providing insights into productivity, downtime reasons, and it enables optimizing OEE by eliminating bottlenecks.

Maintenance Planner

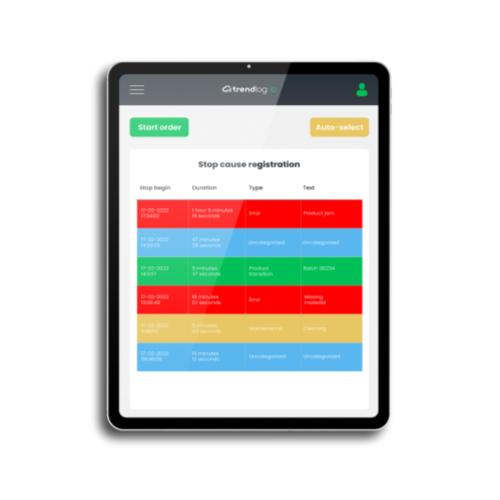

Stop causes

Minimize production costs by identifying the causes of downtime. Operators use tablets to record issues, aiding documentation of bottlenecks and preventing future challenges.

Quality reporting

Energy Meter

Enhance your insight into resource usage with Energy Meter. Track electricity, water, heat, gas, and more to optimize consumption, identify waste, and save costs effectively.

Freemium

Want to try it out? With our Freemium versions, you can try some of our solutions for free, and you’ll have access to graphs, reports and our Maintenance Planner.

Application: Realtime Production

Do you want to know what’s causing you downtime? We can gather real-time data from across your production and give you a comprehensive overview of your production processes. And our Realtime Production application provides you with the insights that can help you make effective improvements on your output and overall efficiency.

Take the first step, reach out to us for a quick demo.

Maintenance Planner keeps Lindab going

– “We use Trendlog to manage and plan our entire maintenance of over 500 machines in 3 different locations in Denmark. We also use OEE to monitor the performance of our machines and to watch for inefficiencies.”

What have you gained from digitizing data from your production?

– “We have gotten a nice overview of our maintenance tasks as well as the load and productivity of key machines, which greatly improves the planning of our time on a daily basis. And it ensures us that we can minimize critical downtime.”

– René Hornshøj,

Maintenance Manager – Lindab A/S, Haderslev

Become a member of Club Trendlog

You will be receiving the latest news, inspiration, customer cases and much more 1-2 times a month. Subscribe to our newsletter here.

The newsletter is for you, who is interested in learning more about digitalization in your production. We are mainly focused on 5 different industries including:

- Agriculture

- Food and beverages

- Plastic manufacturing

- Metal & CNC

- Packaging